Sulfur Concrete for Chemical Industries: Definition, Benefits & Uses

Contents

- 1 What Is Sulfur Concrete, and Why Is It Taken Seriously in Chemical Industries?

- 2 What Is Sulfur Concrete? A Simple, Precise Definition for Project Engineers

- 3 Why Is Sulfur Concrete Attractive for Chemical Industries?

- 3.1 1. Chemical Resistance Against Acids and Salts

- 3.2 2. Fast Execution and Rapid Return to Service

- 3.3 3. Low Permeability and Durability Against Ion Attack

- 3.4 4. Recyclability and Utilization of Surplus Industrial Sulfur

- 3.5 5. No Need for Water, and Simplified “Curing”

- 3.6 Industrial Sulfur Suppliers | Buy Direct and Compare Sellers

- 4 Chemical Composition and the Role of Modified Sulfur

- 5 Applications of Sulfur Concrete in Real Projects

- 6 Limitations and Challenges of Sulfur Concrete

- 7 Comparison Table: Sulfur Concrete vs. Portland Cement Concrete

- 8 Global Trends and New Research in Sulfur-Based Concrete

- 9 A Short Execution Guide for Using Sulfur Concrete in Industrial Projects

- 10 Sulfur Concrete and the Sulfur Supply Chain in Iran

- 11 Final Notes and Key Takeaways for Engineers and Project Managers

What Is Sulfur Concrete, and Why Is It Taken Seriously in Chemical Industries?

What Is Sulfur Concrete? A Simple, Precise Definition for Project Engineers

Definition of Sulfur Concrete

Sulfur concrete, or sulfur-based concrete, is a type of concrete in which molten sulfur is used as the binder instead of Portland cement and water. The grading is based on standard concrete aggregates, but the aggregates should be resistant to acidic and saline environments.

In practice, you mix a “sulfur cement” or “polymerized sulfur” with durable aggregates, and after cooling, you obtain a dense concrete with very low permeability and high chemical resistance.

Differences Between Sulfur Concrete and Conventional Cement Concrete

The main difference is the binder. In Portland cement concrete, cement and water undergo hydration, form crystalline products, and ultimately create a strong concrete matrix. In sulfur concrete, there is no water and no hydration.

Sulfur melts at around 130–140°C, is mixed with additives and aggregates, and after cooling, hardens as a thermoplastic network.

A few key design-level differences

- Sulfur concrete sets several times faster than Portland cement concrete; in many cases, it reaches about 80% of its final strength within 24 hours after casting.

- Sulfur concrete has extremely low permeability to water and aggressive ions (it is close to impermeable), which is a primary advantage in acidic and saline environments.

- Thermal and fire behavior is different; sulfur concrete has more limited high-temperature resistance, and for areas with serious fire risk it must be designed with greater care.

Why Is Sulfur Concrete Attractive for Chemical Industries?

1. Chemical Resistance Against Acids and Salts

The core strength of sulfur concrete is its very high resistance in acidic and saline environments. In Portland cement concrete, hydration products break down upon contact with acids, calcium sulfate and other soluble salts form, and the concrete matrix gradually disintegrates.

In sulfur concrete, the sulfur-based binder is more stable against many acids and salts, and the extremely low permeability limits the migration of aggressive ions.

2. Fast Execution and Rapid Return to Service

In industrial units, downtime has a direct cost. After cooling, sulfur concrete achieves near-final strength and does not require 7 to 28 days of curing like Portland cement concrete.

This is a major advantage for repairs to acid-unit floors, neutralization basins, or wastewater channels that must return to service in the shortest possible time.

3. Low Permeability and Durability Against Ion Attack

The dense, thermoplastic structure of sulfur concrete severely restricts chloride and sulfate ion penetration.

In environments where chloride ions from saline solutions or chloride-bearing acidic solutions attack concrete, this feature can significantly extend service life.

4. Recyclability and Utilization of Surplus Industrial Sulfur

Sulfur is a byproduct of oil, gas, and refining industries. Converting sulfur into sulfur cement and sulfur-based concrete not only reduces long-term sulfur stockpiling, but can also substitute part of the demand for Portland cement—thereby helping reduce carbon dioxide emissions.

5. No Need for Water, and Simplified “Curing”

Unlike Portland cement concrete, sulfur concrete has the advantage that it does not require water during production or after placement.

In regions where access to quality water for making Portland cement concrete is limited, this can be a highly practical alternative.

Also, after demolding, sulfur concrete requires no special curing measures and gains strength simply by cooling.

Industrial Sulfur Suppliers | Buy Direct and Compare Sellers

If you need sulfur with a defined purity and reliable supply for producing sulfur concrete, sulfur cement, or other industrial uses, the Shimico platform makes it possible to access a network of sulfur suppliers in Iran without intermediaries.

- Compare sulfur suppliers by type, purity, and packaging

- Receive updated pricing and delivery terms directly from sellers

- Suitable for sulfur concrete projects, chemical industries, fertilizers, and industrial processing

Chemical Composition and the Role of Modified Sulfur

Sulfur Cement and Polymerized Sulfur

If pure sulfur is melted and cooled on its own, it tends to be brittle and can be unstable over time. To address this, modifiers such as dicyclopentadiene (DCPD) and cyclopentadiene oligomers are used to convert sulfur into a more stable polymeric system.

This “polymerized sulfur” is workable as a liquid at roughly 120–140°C and, after cooling, forms a strong and relatively stable network resistant to phase changes.

Common Additives in Sulfur Concrete

- Organic modifiers (such as DCPD and styrene) to improve toughness and reduce brittleness.

- Active fillers such as fly ash or fine industrial residues that support structural stability and enable the use of industrial byproducts.

- Glass fibers or synthetic fibers to improve crack behavior and increase flexural performance.

- Acid-resistant aggregates such as silica with controlled grading.

Applications of Sulfur Concrete in Real Projects

1) Flooring in Acid, Fertilizer, and Chemical Production Units

One classic application of sulfur concrete is flooring in sulfuric acid production areas, sulfate production lines, and chemical fertilizer plants.

Acidic liquids and vapors that contact the floor can soften and damage Portland cement concrete quickly.

With low permeability and high chemical resistance, sulfur concrete can deliver multiple times the service life in these environments.

2) Acid Tanks, Basins, and Acid Sumps

Neutralization basins, open acid tanks, and sumps that collect corrosive liquids are extremely sensitive locations for concrete corrosion. In such zones, using sulfur concrete for walls and floors—combined with FRP reinforcement—can provide long-term performance.

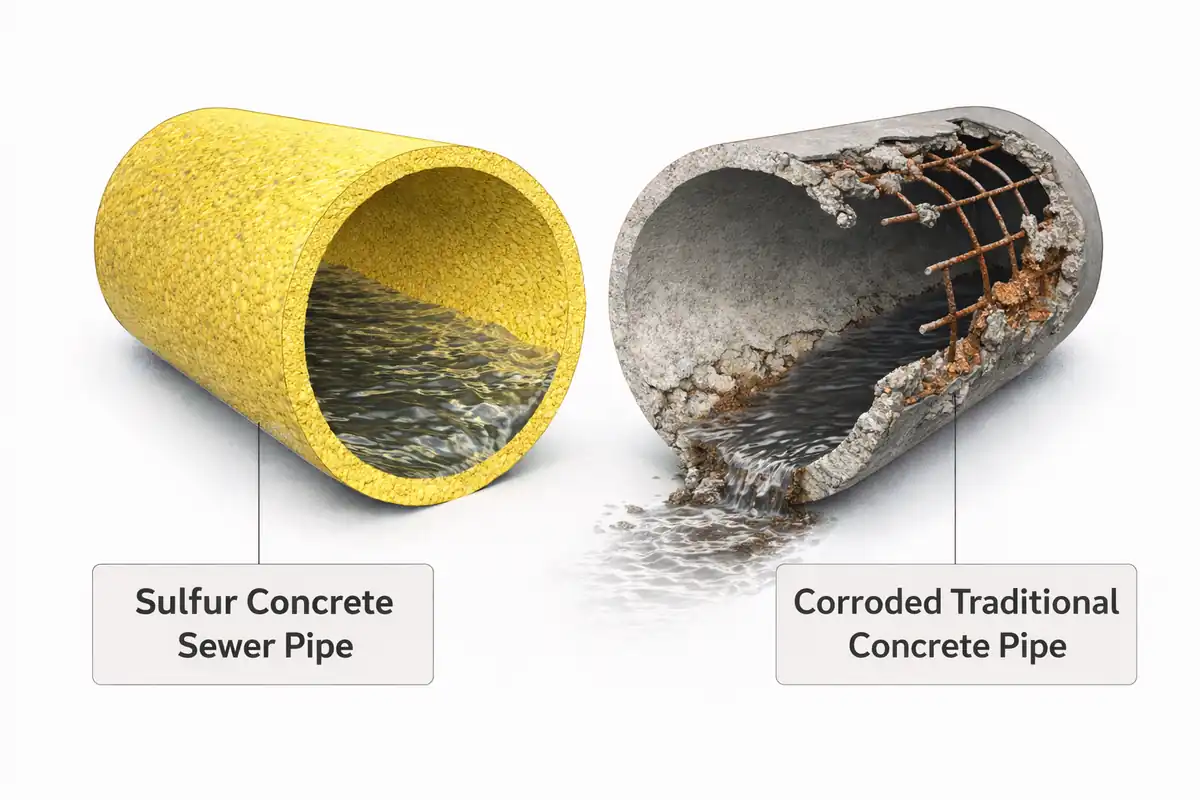

3) Urban and Industrial Sewer Pipes and Channels

Sewer systems, especially under biogenic sulfuric acid attack, are highly aggressive environments for concrete. H2S formation in sewer gases and its conversion into acid on internal surfaces causes severe strength loss and internal lining spalling.

Sulfur concrete is an option worth evaluating for corrosion-resistant sewer pipes and precast components for sewer channels.

4) Pavements and Roadside Precast Components

Precast elements such as industrial pavers, open-channel protection units, and roadway slabs exposed to saline solutions, wastewater, or corrosive chemicals are also target applications for sulfur-based concrete.

Factory production, precise temperature and mix control, and fast on-site installation make these products attractive for industrial projects.

Read more: A comprehensive review of sulfur concrete, sulfur asphalt, and sulfur coatings in infrastructure

Limitations and Challenges of Sulfur Concrete

– Thermal Behavior and Fire

The sulfur binder softens above roughly 120°C and becomes susceptible to ignition above about 170°C.

Therefore, sulfur concrete is not suitable for structures exposed to severe fires, prolonged fire events, or very high temperatures—unless special fire-protection measures are incorporated into the design.

– Low-Temperature Conditions and Freeze–Thaw Cycles

Because sulfur concrete is nearly impermeable, it is highly resistant to freeze–thaw cycling and can be an excellent option in low-temperature conditions involving repeated freezing and thawing.

– Production, Transport, and Execution Requirements

Producing sulfur concrete is not like producing conventional ready-mix concrete. Precise sulfur melt temperature control, mixing within a defined temperature window, oxidation prevention, and strict safety measures for hot-material handling must be built into the production design.

As a result, sulfur concrete is currently more commonly produced as precast products in specialized plants rather than being mixed on-site.

“If you try to execute sulfur concrete using the same habits as Portland cement concrete, you will create risk instead of advantage. This material has its own rules.”

Comparison Table: Sulfur Concrete vs. Portland Cement Concrete

The table below summarizes key performance differences between sulfur-based concrete and conventional cement concrete from the perspective of a structural designer working in corrosive environments. Part of the data is based on the review: A Critical Review on Sulfur-Based Concrete.

| Property | Sulfur Concrete | Conventional Portland Cement Concrete |

|---|---|---|

| Binder | Modified sulfur (thermoplastic) | Hydraulic Portland cement |

| Time to early strength | Within hours after cooling | Typically 3–7 days |

| Permeability to water/ions | Very low | Moderate to high, depending on mix design |

| Resistance to acids/salts | High | Low to moderate |

| Recyclability | Can be remelted and recycled | Binder is practically non-recyclable |

| Fire behavior | Sensitive to high heat and fire | Better fire stability |

Global Trends and New Research in Sulfur-Based Concrete

Sulfur Polymer Concrete as a Sustainable Material

In recent years, research on sulfur polymer concrete has expanded, especially using surplus sulfur and industrial byproducts.

These systems aim to use sulfur and industrial fillers such as fly ash and refinery residues to both address sulfur stockpiling and reduce reliance on Portland cement production.

Combining Sulfur Concrete with Next-Generation Materials

New research studies sulfur-based concrete alongside geopolymer concrete, nano-silica systems, and hybrid binder systems.

The goal is to design systems that provide long-term performance in highly corrosive environments such as petrochemical units, fertilizer plants, and advanced wastewater facilities—while also offering a lower carbon footprint than Portland cement concrete.

A Short Execution Guide for Using Sulfur Concrete in Industrial Projects

Mix Design

- Select acid-resistant aggregate (silica) with controlled grading and low moisture content.

- Design the sulfur-to-aggregate ratio based on standard guidelines and sulfur-cement manufacturer data (ACI 548.2R).

- Choose an appropriate modifier based on service conditions (temperature, chemical exposure, and toughness requirements).

Production and Transport Notes

- Heat sulfur to about 130–140°C in temperature-controlled tanks equipped with suitable agitation.

- Add modifiers at the specified temperature and ensure full mixing before introducing aggregates.

- Maintain mix temperature during transport to the casting point using trucks or hot-material handling systems designed for this purpose.

- Control ventilation and site safety due to potential sulfur vapors at elevated temperatures.

On-Site Quality Control

– Control mix temperature at placement.

– Sample sulfur concrete for compressive strength testing and surface structure evaluation.

– Check bond and reinforcement compatibility based on standards and manufacturer recommendations.

Sulfur Concrete and the Sulfur Supply Chain in Iran

Why Is Stable Access to Sulfur Important?

Choosing sulfur-based concrete for an industrial project is not only a technical decision.

If you intend to use this material at meaningful scale, you must be sure the sulfur and modifier supply chain is available, stable, and traceable.

Sulfur is generally sourced from refineries and sour-gas processing units, and quality, form (granules vs. lumps), and purity directly affect sulfur cement performance.

The Role of Shimico in Sourcing Sulfur-Concrete Raw Materials

Need sulfur concrete? Find everything from sulfur to additives on Shimico

If you are designing or executing a project that requires sulfur concrete, your starting point is reliable raw-material sourcing. The

Shimico chemical materials platform

makes it possible to:

- Compare different sulfur suppliers by specifications, packaging, and supply capacity.

- Request quotations for sulfur with suitable purity for sulfur cement production.

- Gradually build a network of suppliers for additives related to sulfur-based concrete.

- Track quotations, delivery terms, and technical documents within a single platform.

If you want to seriously evaluate sulfur concrete for your next acid-floor, wastewater channel, or neutralization basin project, visit

Shimico and review the relevant chemical material suppliers.

Submit one real inquiry for sulfur and additives on Shimico to get a clearer, more realistic picture of feasibility and cost for your own project.

Final Notes and Key Takeaways for Engineers and Project Managers

When Is Sulfur Concrete a Smart Choice?

- When the service environment is highly acidic or saline and experience shows Portland cement concrete has a short lifespan.

- When long shutdowns for repairs are not acceptable and you need flooring or containment systems that can return to service within hours.

- When stable access to sulfur and additives is available through a defined, traceable supply network.

- When the project is not in a high fire-risk environment, or when you have a clear fire-protection plan.

- When you do not have access to sufficient, good-quality water for producing Portland cement concrete.

A Direct Question for You

If, in your unit, the acid-floor, neutralization basin, or wastewater channel must be replaced every three to five years due to concrete corrosion, is it time to at least pilot a solution like sulfur concrete in one section of the site?

The next step is simple: review your corrosion hot-spots, choose a suitable pilot location, and at the same time submit a few inquiries through Shimico for suitable sulfur and additives. This combination leads to a decision that is more technical, more economical, and more realistic.

Last Seen

Users Comment

Sulfur for Infrastructure: Asphalt, Coatings & Concrete

The Top 10 Industrial Chemicals Shaping the World in 2025

How Urea Can Hydrate and Exfoliate Your Skin

Sodium carbonate| Soda ash; features and applications

Copper Sulfate; Features and applications

Sulfur; Features and applications

Zinc sulfate; Features and applications

Urea; Features and applications

Sodium bicarbonate; Features and applications

Ammonium Sulfate; Features and applications

What is the use of caustic soda? An Overview of the caustic soda uses

Caustic soda flakes and the methods of production