The Top 10 Industrial Chemicals Shaping the World in 2025

پPicture yourself in the heart of a chemical plant, where pipelines pulse with purpose and the air hums with the promise of progress. These are the chemicals that quietly shape our world, from the crops that feed us to the devices that connect us.

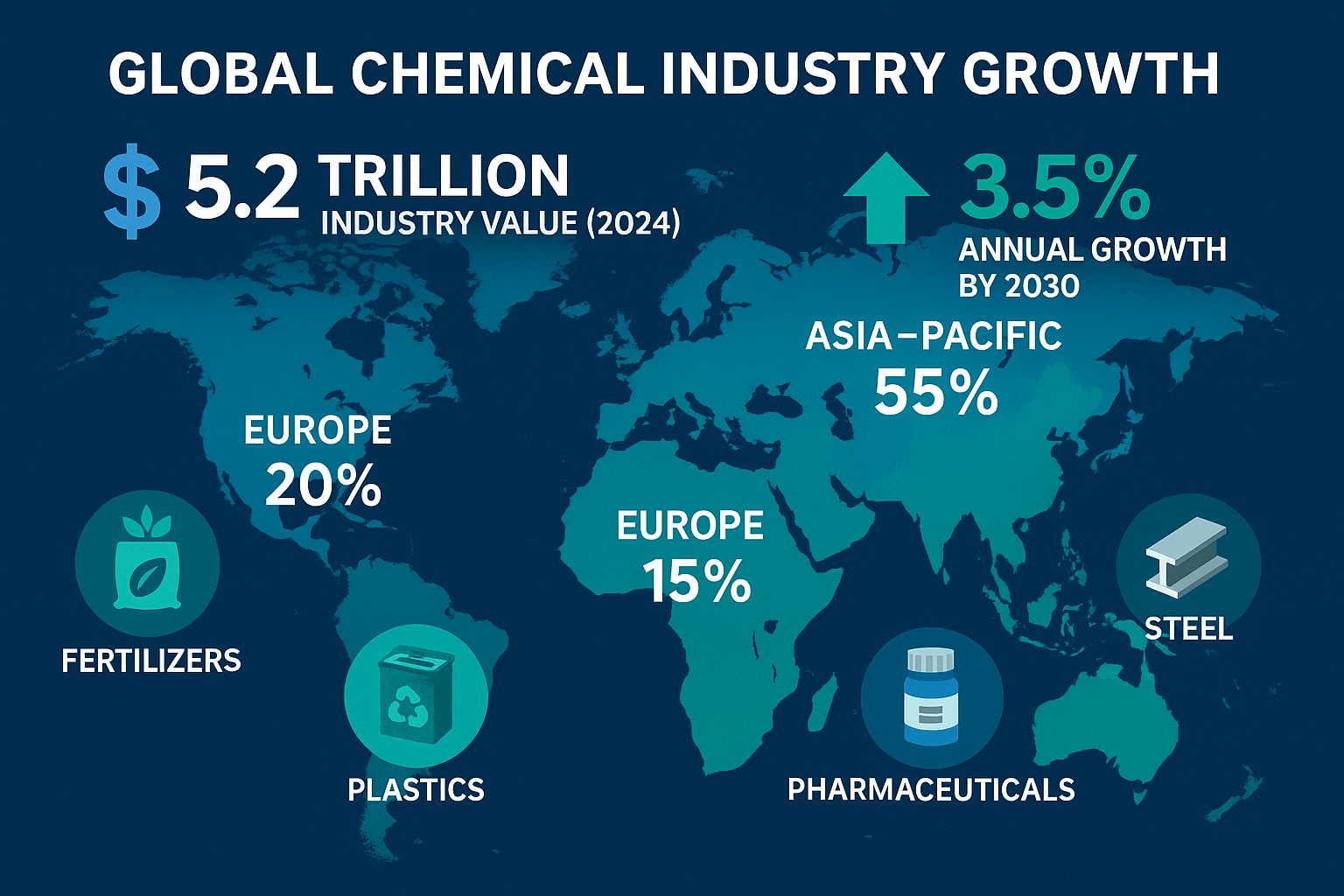

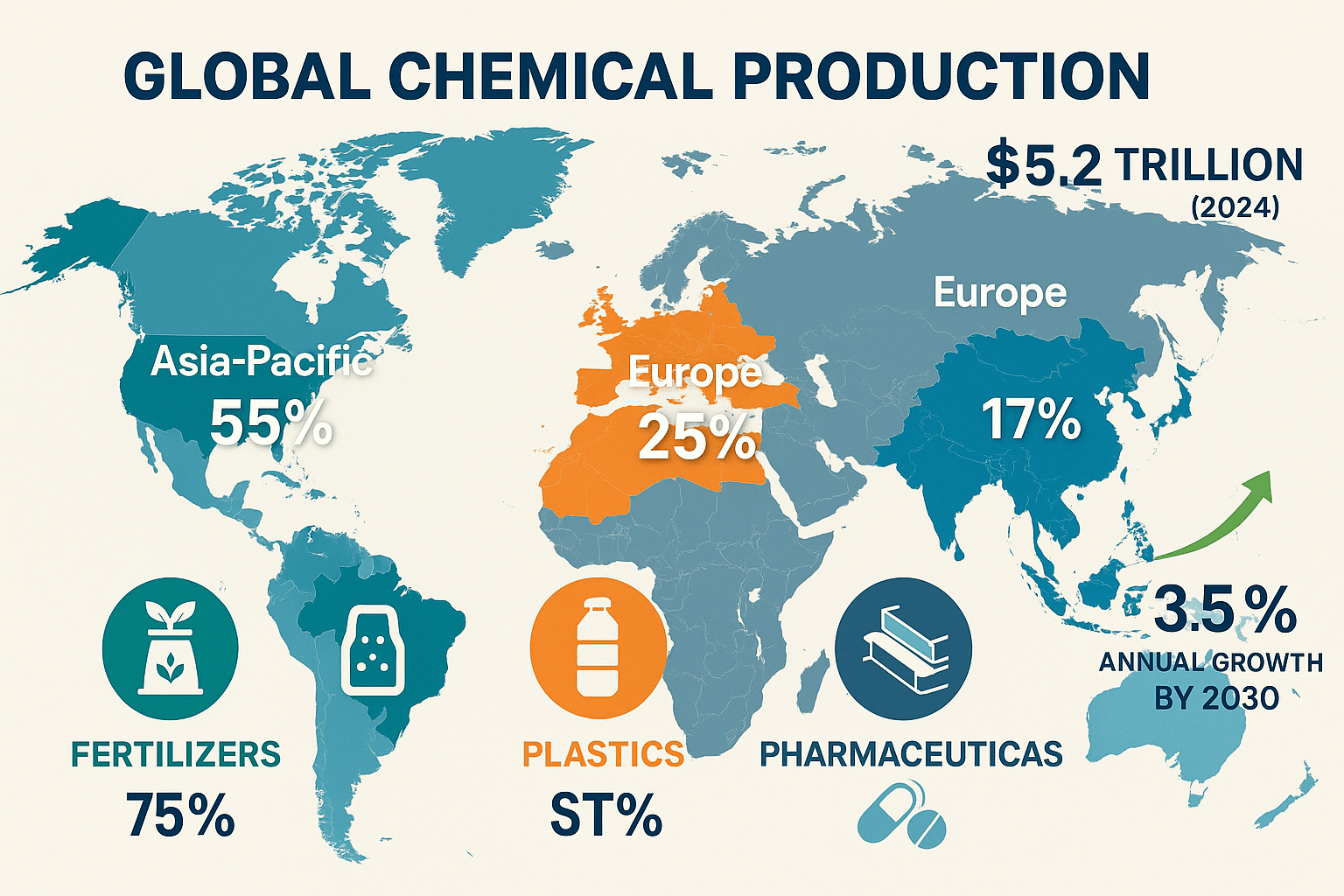

In 2024, the global chemical industry generated $5.2 trillion, with a projected 3.5% annual growth through 2030, per Deloitte’s 2025 Chemical Industry Outlook. Among thousands of compounds, 10 giants stand out, driving industries with their massive production and versatile applications.

This article dives deep into their stories, from how they’re made to their global impact. Whether you’re curious about modern manufacturing or seeking industry insights, let’s explore the chemicals that make it all happen.

Contents

- 1 The Heartbeat of Industry: Why These Compounds Matter

- 2 The Top 10 Chemicals Redefining 2025

- 2.1 1. Sulfuric Acid (H₂SO₄): The Universal Catalyst

- 2.2 2. Nitrogen (N₂): The Invisible Enabler

- 2.3 3. Ethylene (C₂H₄): The Plastics Pioneer

- 2.4 4. Oxygen (O₂): The Lifeblood of Industry

- 2.5 5. Propylene (C₃H₆): The Versatile Innovator

- 2.6 6. Chlorine (Cl₂): The Guardian of Purity

- 2.7 7. Ethylene Dichloride (C₂H₄Cl₂): The Silent Architect of Urban Life

- 2.8 8. Phosphoric Acid (H₃PO₄): The Nourisher of Fields

- 2.9 9. Ammonia (NH₃): The Fertilizer Champion

- 2.10 10. Sodium Hydroxide (NaOH): The Everyday Essential

- 3 The Big Picture: A Comparative Snapshot

- 4 The Future: Growth Meets Green Innovation

The Heartbeat of Industry: Why These Compounds Matter

Driving Global Economies

The chemical sector is a powerhouse, contributing 7% to global GDP. In 2023, it produced 2.3 billion metric tons, with basic compounds making up 60% of that volume. Asia-Pacific leads with 55% of output, followed by Europe and North America. These materials fuel agriculture, construction, electronics, and more, turning raw resources into everyday essentials.

The Green Revolution

Progress isn’t without hurdles. Supply chain challenges and stricter environmental rules are pushing the industry toward sustainability. Green chemistry investments surged 15% last year, signaling a shift. Balancing demand with eco-friendly practices is a tightrope walk, but it’s shaping the future of these compounds.

Why These 10?

These 10 chemicals, chosen for their massive production often exceeding 100 million metric tons annually are the backbone of industry. Drawing from Statista and ChemAnalyst, this list uncovers their unique roles and trends.

The Top 10 Chemicals Redefining 2025

Each chemical below is a titan, with production scales and applications that shape our world. I’ve crafted each section to highlight their uniqueness, weaving in data and storytelling for a fresh perspective.

1. Sulfuric Acid (H₂SO₄): The Universal Catalyst

Sulfuric Acid’s Path to Power

This dense, colorless liquid, with a density of 1.84 g/cm³, is born through the contact process, where sulfur from oil refining is oxidized and hydrated in a high-energy ballet. Modern plants achieve near-100% efficiency, making sulfuric acid a marvel of industrial precision that fuels countless processes.

Sulfuric Acid’s Global Dominance

In 2024, production hit 261 million metric tons, with China leading at 19 million metric tons of sulfur equivalent, per Statista. Valued at $23.2 billion, the market grows at an 11.2% CAGR through 2034, per Global Market Insights.

Sulfuric Acid’s Role in Feeding the World

Sulfuric acid powers 60% of fertilizer production, turning phosphate rock into nutrients for crops. It also refines petroleum, processes metals, and fuels car batteries. “It’s the cornerstone of food security,” says an analyst from Emergen Research.

Sulfuric Acid’s Green Evolution

Asia’s agricultural boom drives demand, but sulfur dioxide emissions are a challenge. EU regulations demand 99% capture, pushing for advanced scrubbers and recycling systems to keep sulfuric acid sustainable.

2. Nitrogen (N₂): The Invisible Enabler

Nitrogen’s Journey from Air to Industry

This odorless gas, making up 78% of Earth’s atmosphere, is captured through fractional distillation of liquefied air. With a boiling point of -196°C, nitrogen’s inert nature makes it a silent hero in industries requiring stability, from farms to high-tech cleanrooms.

Nitrogen’s Market Momentum

The market reached $42.6 billion in 2023, with production around 100 million metric tons annually, growing at a 5.5% CAGR, per Global Market Insights. The U.S. and China lead, driven by agriculture and electronics.

Nitrogen’s Impact on Food and Tech

Transformed into ammonia via the Haber-Bosch process, nitrogen fuels fertilizers. It also preserves food and creates inert atmospheres for semiconductors, as noted by Linde Gas. Your fresh snacks owe a lot to nitrogen.

Nitrogen’s Sustainable Future

Set to hit $80.1 billion by 2032, the market faces energy challenges. Renewable-powered plants are emerging to reduce emissions.

3. Ethylene (C₂H₄): The Plastics Pioneer

Ethylene’s High-Heat Creation

This flammable gas, with a sweet scent, is born through steam cracking of hydrocarbons like naphtha or ethane. Requiring extreme temperatures and precision, ethylene’s production is a complex dance that powers 95% of its global supply.

Ethylene’s Market Surge

Output hit 177 million metric tons in 2024, with a 3.62% CAGR through 2035, per ChemAnalyst. The $203.74 billion market grows at 6.2% annually, per Straits Research.

Ethylene’s Role in Everyday Products

Ethylene fuels polyethylene, consuming 60% of supply, for packaging, pipes, and films. It’s also in antifreeze and detergents. “Ethylene drives modern packaging,” says Straits Research.

Ethylene’s Green Ambitions

E-commerce boosts demand, but emissions from cracking are a concern. Bio-based ethylene from ethanol is gaining traction, targeting carbon neutrality by 2035.

4. Oxygen (O₂): The Lifeblood of Industry

Oxygen’s Path to Purity

This reactive gas, with a boiling point of -183°C, is isolated via cryogenic distillation in air separation units. Oxygen’s ability to support combustion and life makes it indispensable across manufacturing and healthcare.

Oxygen’s Market Expansion

The market was $53.1 billion in 2023, set to reach $142.58 billion by 2032, per SkyQuest. Production hovers around 80 million metric tons annually.

Oxygen’s Role in Steel and Healing

Steel production uses 65% of oxygen, enhancing furnace efficiency. It’s also vital in chemical synthesis and medical ventilators, especially post-2020.

Oxygen’s Efficiency Drive

An 8.5% CAGR reflects healthcare and metal demand. Energy-intensive production pushes for efficient systems.

5. Propylene (C₃H₆): The Versatile Innovator

Propylene’s Byproduct Beginnings

This colorless gas, an alkene like ethylene, is produced via steam cracking or propane dehydrogenation, often as a byproduct. Propylene’s versatility shapes modern manufacturing.

Propylene’s Market Growth

Capacity hit 160 million metric tons in 2023, with a $112.02 billion market growing at 3.76% CAGR, per Precedence Research.

Propylene’s Impact on Products

Polypropylene, taking 70% of supply, is in automotive parts and packaging your car’s dashboard and water bottle.

Propylene’s Sustainable Shift

Consumer goods drive growth, with on-purpose production cutting waste. Bio-based options are emerging.

6. Chlorine (Cl₂): The Guardian of Purity

Chlorine’s Electrolysis Origins

This greenish-yellow gas, with a sharp odor, is produced via electrolysis of sodium chloride brine, alongside sodium hydroxide, in a carefully controlled process.

Chlorine’s Global Reach

Production hit 97.33 million metric tons in 2023, with forecasts of 128.95 million by 2030, per Statista.

Chlorine’s Role in Clean Water and Plastics

Chlorine powers PVC production and water purification, ensuring safe drinking water. It’s also in disinfectants and pharmaceuticals.

Chlorine’s Eco-Friendly Path

A 4.5% CAGR is driven by sanitation. Mercury-free technologies reduce environmental impact, especially in Europe.

7. Ethylene Dichloride (C₂H₄Cl₂): The Silent Architect of Urban Life

Forging Ethylene Dichloride’s Path to PVC

Deep within industrial reactors, ethylene dichloride comes to life as ethylene and chlorine merge in a meticulously controlled reaction. This clear, sweet-smelling liquid is the result of a process that balances precision with safety, transforming volatile gases into a stable compound that’s the foundation of modern construction materials.

Ethylene Dichloride’s Global Market Surge

In 2022, the world produced 45 million metric tons of ethylene dichloride, with a projected 3.61% CAGR driving the market to $30.1 billion by 2035, according to ChemAnalyst. China’s rapid urbanization fuels this growth, with the U.S. close behind.

Ethylene Dichloride’s Role in Shaping Cities

Ethylene dichloride’s legacy lies in its transformation into polyvinyl chloride (PVC), the material behind water pipes, electrical cables, and building components. Nearly all its production feeds into PVC manufacturing, making it indispensable for urban development. “Ethylene dichloride is the unsung hero of our skylines,” says an expert from ChemAnalyst.

Ethylene Dichloride’s Sustainability Challenge

Producing ethylene dichloride requires careful handling due to its toxicity, with EU regulations enforcing strict environmental standards. Innovations like closed-loop systems and greener chlorine sourcing are reducing emissions.

8. Phosphoric Acid (H₃PO₄): The Nourisher of Fields

Phosphoric Acid’s Journey from Rock to Crop

This viscous acid transforms phosphate rock into nutrients through the wet process, a method producing both industrial and food-grade supplies with remarkable efficiency.

Phosphoric Acid’s Market Rise

Production reached 42 million metric tons in 2024, with a 4.13% CAGR, per ChemAnalyst. The $35.2 billion market in 2023 will hit $54 billion by 2032.

Phosphoric Acid’s Role in Global Food

Fertilizers, consuming 80% of supply, drive agriculture, with smaller roles in food additives and detergents. It’s behind your morning cereal.

Phosphoric Acid’s Waste Challenge

Agricultural demand is strong, but phosphogypsum waste pushes for innovative management solutions.

9. Ammonia (NH₃): The Fertilizer Champion

Ammonia’s Creation via Haber-Bosch

This pungent, water-soluble gas is born through the energy-intensive Haber-Bosch process, combining nitrogen and hydrogen to fuel global agriculture.

Ammonia’s Market Scope

Output was 194.80 million metric tons in 2024, with a 1.90% CAGR, per Expert Market Research.

Ammonia’s Impact on Harvests

Fertilizers take 70% of supply, with roles in refrigerants and explosives completing its portfolio.

Ammonia’s Green Transformation

Green production using renewables is cutting the carbon footprint, ensuring sustainable growth.

10. Sodium Hydroxide (NaOH): The Everyday Essential

Sodium Hydroxide’s Birth from Brine

This white solid, a strong base, is produced alongside chlorine via brine electrolysis, a process balancing efficiency and output.

Sodium Hydroxide’s Market Growth

The market hit $46.59 billion in 2024, set to reach $73.75 billion by 2034, per Precedence Research.

Sodium Hydroxide’s Role in Daily Life

It’s in pulp, paper, soaps, and textiles, crafting products we use daily.

Sodium Hydroxide’s Byproduct Challenge

A 4.7% CAGR is driven by textiles, with chlorine byproduct management a key focus.

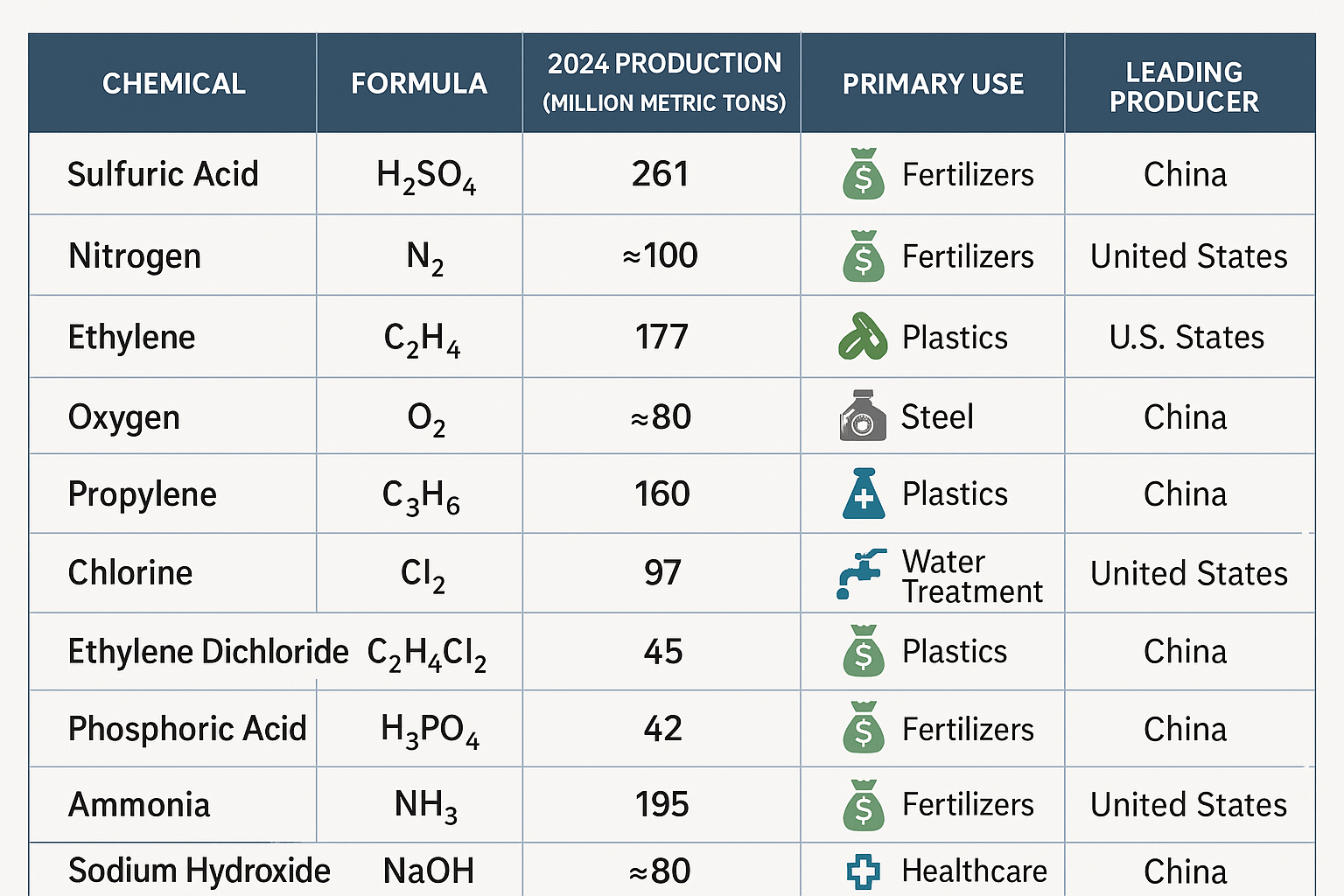

The Big Picture: A Comparative Snapshot

| Chemical | Formula | 2024 Production (Million Metric Tons) | Primary Use | Market Growth (CAGR) | Leading Producer |

|---|---|---|---|---|---|

| Sulfuric Acid | H₂SO₄ | 261 | Fertilizers | 11.2% | China |

| Nitrogen | N₂ | ~100 | Fertilizers | 5.5% | United States |

| Ethylene | C₂H₄ | 177 | Plastics | 6.2% | United States |

| Oxygen | O₂ | ~80 | Steel | 8.5% | China |

| Propylene | C₃H₆ | 160 | Plastics | 3.76% | China |

| Chlorine | Cl₂ | 97 | PVC | 4.5% | United States |

| Ethylene Dichloride | C₂H₄Cl₂ | 45 | PVC | 3.61% | China |

| Phosphoric Acid | H₃PO₄ | 42 | Fertilizers | 4.13% | China |

| Ammonia | NH₃ | 195 | Fertilizers | 1.90% | China |

| Sodium Hydroxide | NaOH | ~80 | Paper/Soap | 4.7% | United States |

The Future: Growth Meets Green Innovation

The industry faces soaring demand think Asia’s agricultural boom, e-commerce, and healthcare but sustainability is critical. Green ammonia could cut emissions by 40% by 2030, per McKinsey. Bio-based production and mercury-free processes are rising. These chemicals are vital, but their future is green. Stay ahead with ReAgent’s insights or McKinsey’s reports. Can growth and green coexist? Share your thoughts below.

Last Seen

(3 Votes)

(3 Votes)

Users Comment

How Urea Can Hydrate and Exfoliate Your Skin

Sodium carbonate| Soda ash; features and applications

Copper Sulfate; Features and applications

Sulfur; Features and applications

Zinc sulfate; Features and applications

Urea; Features and applications

Sodium bicarbonate; Features and applications

Ammonium Sulfate; Features and applications

What is the use of caustic soda? An Overview of the caustic soda uses

Caustic soda flakes and the methods of production

Analysis of September manufacturing trends in Asia

The impact of growth in major Asian economies on petrochemical demand