In general, it is necessary to consider some things when buying Caustic Soda Flakes. In short, the price of the Caustic Soda Flakes, the quality of the material, packaging and timely delivery are very important, which are explained in more detail below.

The top 10 Caustic Soda Flakes suppliers in Iran

| 1 | Shooshtar petrochemical |

| 2 | Kimia Pars Co Caustic soda flakes |

| 3 | Petro Gohar Pars |

| 4 | Chloran |

| 5 | Nirouchlor |

| 6 | Persian Chemical |

| 7 | Almas Tejarat Etemad Iranian |

| 8 | Taheri Trading Co. |

| 9 | Tegin Tejarat Payam |

| 10 | Bamdad Petro Parsian |

Choosing the right caustic soda

Product quality

According to the 364 standard, the purity of grade 1 Caustic Soda Flakes is at least 98% and this amount for grade 2 product is at least 95%. Caustic Soda Flakes or caustic soda with the scientific name of sodium hydroxide has properties that buyers of this substance should buy knowing these properties. Among other things, it is necessary to know the top Caustic Soda Flakes suppliers in order to make your purchase from them.

Caustic Soda Flakes should be free of any moisture. If moisture penetrates into the packaging, sodium hydroxide will clump and is used as caustic soda grade 2, mostly in recycling industries. You need to know that some fraudulent manufacturers mix some salt with the caustic soda product due to the cheapness of the salt.

High-quality caustic soda is sold completely white in appearance and without yellowing. The shelf life of caustic soda is 6 months, which means that if the packaging is suitable, this substance should not clump for 6 months. Before buying, check the photo, analysis and other documents of this substance in the documents section on the advertisement page of Shimico website and make sure it is free of heavy metals.

Sampling of sodium hydroxide is doing according to Iranian national standard No. 2529. When buying, pay attention to the standards, including ISO 9001, 9002 and 18001, and the date of production and expiration of the material. It is possible to produce Caustic Soda Flakes by two methods: membrane and chloralkaline. Soda Flakes produced by the membrane method (membrane grade) has a higher quality due to less heavy metals.

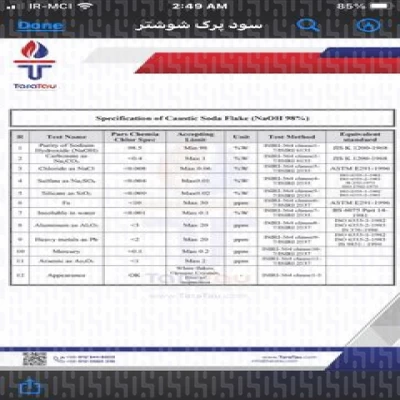

You can see the physical and chemical properties of sodium hydroxide in the table below:

| Physical and chemical properties | |

| Chemical formula | NaOH |

| Molar mass | 39.9971 g mol−1 |

| Appearance | White, waxy, opaque crystals |

| Odor | Odorless |

| Density | 2.13 g/cm3 |

| Melting point | 323 °C (613 °F; 596 K) |

| Boiling point | 1,388 °C (2,530 °F; 1,661 K) |

| Solubility in water | 418 g/L (0 °C) 1000 g/L (25 °C) 3370 g/L (100 °C) |

Caustic soda production methods

- Caustic soda produced by membrane method or membrane cell electrolysis (membrane grade) has a higher quality due to less heavy metals.

- In the diaphragm cell electrolysis method, a stream of salt water moves from the anode to the cathode and separates hydrogen and chlorine gas.

- In the mercury cell electrolysis method, sodium is transferred in the form of amalgam ions to a separate chamber and reacts with water, and finally caustic soda solution and hydrogen gas are produced.

- In the chlor-alkali process, sodium chloride aqueous solution is usually used as feed and raw material, and chlorine (gaseous chlorine), liquid soda and hydrogen are obtained as the final products of this process.

Caustic soda uses

The uses of sodium hydroxide in various industries include the following:

| Related industry | usage |

| Wood and cellulose | Bleaching, pulping chemicals, baking paper |

| Laboratory | Buffer |

| Leather and tanning | Degreaser, hair remover |

| Water treatment | Purifying chemicals, neutralizing agents, cleaning agents |

| Oil, gas and petrochemical | Basic chemicals, drilling mud |

| Building, construction and road | Retarder |

| Food and additives | Sweetness |

Caustic soda Storage & Packaging

Basic packaging

The best type of packaging for caustic soda products is in the form of double-layer PP/PE bags, jumbo bags or metal barrels. It is possible to place Caustic Soda Flakes bags inside 1000 or 1250 kg jumbo bags. The strength of the stitching of the bags must be such that it is not damaged during transportation and handling and the product is completely safe. The best type of thread used in sewing caustic soda bags is anti-UV thread. Sodium hydroxide packaging should have information such as production and expiration date, safety notes and MSDS, as well as purity percentage, weight and product receiving standards. The packaging must be completely suitable, without moisture, discoloration and tears. Top 10 Soda Flakes fit providers take these into consideration.

Storage, loading and delivery

Caustic soda should be stored away from moisture and sunlight. Please note that the product is highly sensitive to moisture and changes its shape. The storage space of sodium hydroxide should have a temperature of less than 40 degrees and preferably between 29 and 38 degrees. Also, proper ventilation of the warehouse to remove moisture is important. Loading Caustic Soda Flakes must be done in a completely principled and safe manner. One of the parameters that caustic soda customers care about is timely delivery. The floor of the caustic soda transporter must be healthy and not have nails. The process of loading and unloading should not be done under the sunlight and it should be noted that the bags are not damaged or torn. Cars must have roofs or tents. If you have requested a QC report from the manufacturer, You can receive this report when the cargo is delivered.

The competitive price

One of the concerns of the buyers of this material has always been to find the Soda Flakes at a reasonable price. As you know, this material is sold in large quantities by petrochemicals and in large, medium and small quantities by chemical companies. The top 10 Soda Flakes suppliers in Iran pay attention to providing the right price to the customer. In order to make it easier to compare the price of Soda Flakes, Shimico has provided buyers with a complete list of advertisements of sodium hydroxide suppliers, so that they can start their buying process more confidently by finding a suitable and competitive price. You can also see customer feedback in this list.